In the process of product inspection, the industry generally adopts Acceptance Quality Limit (AQL) as the sampling standard. Acceptance Quality Limit (AQL), formerly known as the acceptable quality level, was decades ago by Harold F. Developed by Dodge and fine-tuned by him and other statistical experts over the years.

Today, AQL is widely regarded as an effective method of random sampling during product inspection, taking into account the computational risks of customers and suppliers. It provides a quantitative reference for buyers and suppliers to how many defective products are accepted in one inspection according to the AQL sampling guide.

Explain defects under product inspection

One of the key things you need to know before talking about AQL is defects. For mass production, it is inevitable that the product has different degrees of defects, which directly affects the economic benefits of buyers.

The inspection, mainly carried out as the final random inspection, provides an objective and measurable quality assessment of the products that the buyer will receive. Based on the inspection results, the buyer can understand the possible defects of the products of the batch of products, so as to make a decision on the arrangement of the goods.

Generally speaking, there are several explanations for these three types of defects:

Critical defects: Defects that do not comply with mandatory regulations and/or affect consumer/end-user security.

Major defects: Defects that lead to product failures and reduced product availability or saleability to a large extent.

Minor defects: Defects that deviate from quality standards but are unlikely to reduce product availability or sellability.

For example, a needle found on a children's trousers is considered a critical defect, the faulty battery in the flashlight is the major defect, and the small scratches on the wardrobe are minor defects.

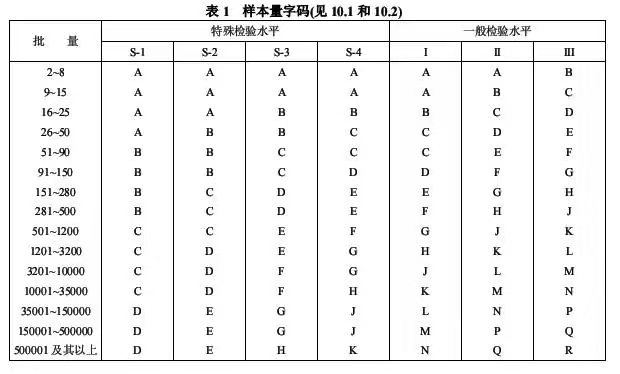

Understand the general and special sampling levels

The AQL guide consists of two sampling levels: the general sampling level and the special sampling level, which, as the name implies, is mainly used for special purposes, such as destructive inspection.

Decode AQL level settings

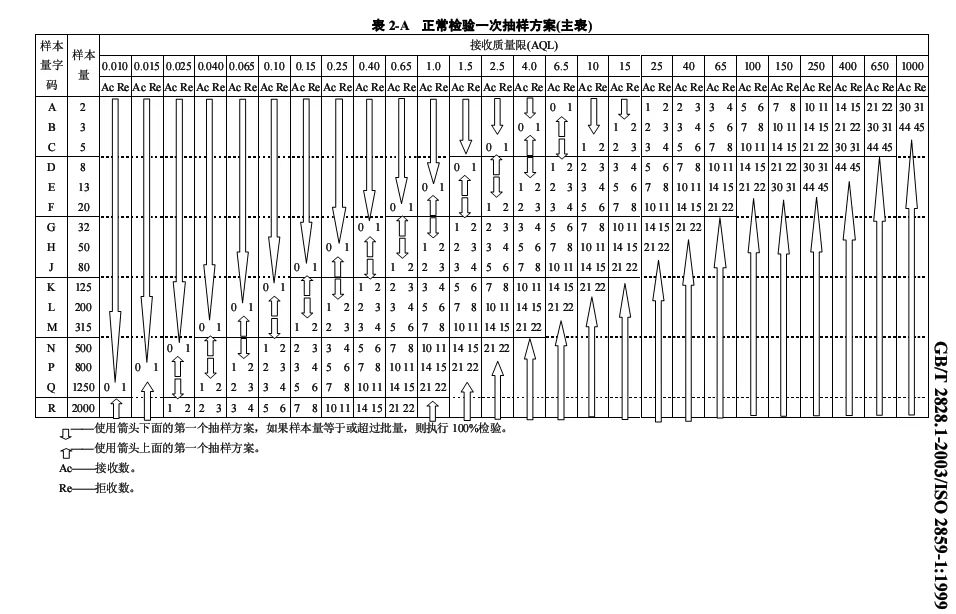

It is common for buyers to hold varying degrees of strictness and expectation for the quality of their products, which leads to different AQL level settings.

Under normal inspection, the AQL level is between 0.065 and 6.5. The larger the AQL level, the looser the inspection.

For general consumer goods inspection, the AQL level is usually set to 2.5, which means zero tolerance for critical defects, 2.5 tolerance for major defects and 4 tolerance for minor defects.

Product inspection is very useful for understanding the quality requirements of goods before shipment. The effective use of AQL provides good insight and objective quality measurement standards, so buyers can make relevant decisions on purchase orders. If buyers need help in formulating their own inspection plans and requirements, we will be happy. I intend to use our expertise and experience in this industry to help.